Aluminosilicate Glass Wafers

Overview

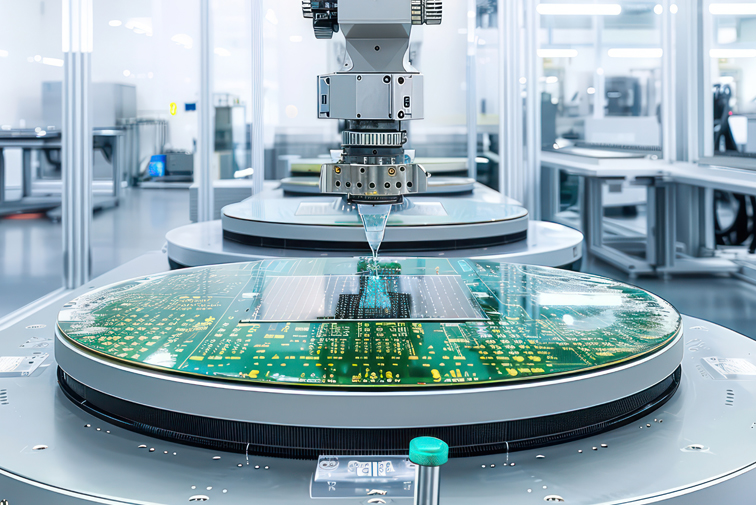

Aluminosilicate glass wafers are highly durable and lightweight wafers known for their excellent mechanical strength, chemical resistance, and thermal stability. These wafers are composed of silica and alumina, which provide enhanced resistance to scratches, impacts, and thermal shock. Aluminosilicate glass is commonly used in applications that require a combination of toughness and clarity, making it ideal for consumer electronics, display technologies, and advanced optical devices.

Product Features

High Mechanical Strength

Aluminosilicate glass wafers offer superior scratch and impact resistance, making them highly durable and well-suited for demanding environments.

Chemical Resistance

Aluminosilicate glass resists degradation from a wide range of chemicals, providing long-lasting performance in corrosive environments.

Thermal Stability

These wafers provide excellent thermal resistance, maintaining their strength and integrity under high-temperature conditions.

Lightweight

Despite their strength, aluminosilicate glass wafers are lightweight, which is advantageous for applications in electronics and portable devices.

- Wafer Sizes: Available in 2-inch, 4-inch, 6-inch, and 8-inch diameters.

- Thickness: Standard and customizable thickness options to fit specific application needs.

- Surface Finish: Precision-polished surfaces are available for applications that require high optical clarity and smoothness.

- Thermal Properties: High thermal stability, suitable for temperatures up to 600°C.

- Optical Properties: Transparent in the visible spectrum with excellent clarity and low distortion.

- Consumer Electronics: Aluminosilicate glass wafers are widely used in the production of touchscreens and display covers for smartphones, tablets, and other consumer electronics due to their durability and optical clarity.

- Optics and Photonics: These wafers are used in optical devices and photonics where mechanical strength, transparency, and resistance to environmental factors are critical.

- Advanced Coatings: Aluminosilicate glass is often used as a substrate for protective coatings in both industrial and consumer applications.

- Microfluidics: In microfluidic devices, aluminosilicate glass provides the necessary durability and chemical resistance required for precision fluid handling and analysis.