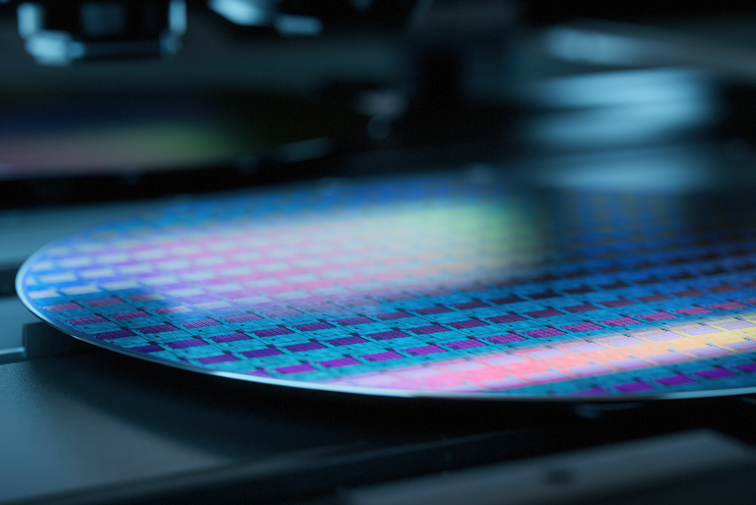

Diamond Wafers

Overview

Diamond wafers represent the pinnacle of advanced material technology, offering extraordinary thermal conductivity, electrical insulation, and mechanical hardness. Synthetic diamond wafers are engineered using advanced techniques such as chemical vapor deposition (CVD), enabling their use in a variety of cutting-edge applications where traditional materials fall short. Their unique properties make diamond wafers ideal for high-power electronics, thermal management systems, quantum computing, and even extreme environment sensors. Diamond’s unparalleled hardness and thermal performance make it indispensable in applications that demand longevity and resilience under intense conditions.

Product Features

Unmatched Thermal Conductivity

Diamond wafers have the highest thermal conductivity of any known material, significantly outperforming other materials in heat dissipation, which is critical for high-power electronic devices and thermal management solutions.

Mechanical Hardness

Diamond’s exceptional hardness and resistance to wear make these wafers ideal for applications that require robust materials, including cutting tools, sensors, and high-precision optics.

Wide Bandgap Semiconductor Properties

In certain applications, diamond can act as a wide bandgap semiconductor, useful for high-power, high-frequency electronic devices such as transistors and diodes.

Electrical Insulation

Diamond wafers serve as excellent electrical insulators while simultaneously providing superior thermal performance, making them essential for advanced electronic applications that require efficient heat management without compromising electrical isolation.

- Wafer Sizes: Common sizes range from 2-inch to 4-inch diameters, with custom sizes available for specialized applications.

- Thickness: Typically ranging from 100 µm to 500 µm, customizable based on application needs.

- Surface Finish: Available in polished, semi-polished, or unpolished finishes depending on the application, such as for optics or electronics.

- Thermal Conductivity: Exceeds 2000 W/mK, far surpassing traditional semiconductor materials like silicon and silicon carbide.

- Bandgap: Wide bandgap of approximately 5.5 eV, suitable for high-power and high-frequency electronic applications.

- Crystallinity: Available in single-crystal or polycrystalline forms, depending on the specific performance requirements.

- High-Power Electronics: Diamond wafers are increasingly used in power electronic devices where efficient heat dissipation is critical to performance and longevity, such as in RF power amplifiers and high-power transistors.

- Quantum Computing: Diamond wafers are playing an emerging role in quantum computing, particularly in the creation of qubits using nitrogen-vacancy (NV) centers in diamonds for quantum data processing.

- Thermal Management Systems: Due to their superior thermal conductivity, diamond wafers are used in thermal spreaders and heat sinks in electronics and photonics, significantly enhancing device performance and reliability.

- Extreme Environment Sensors: Diamond’s durability and resistance to extreme temperatures and pressures make it ideal for sensors used in harsh environments, such as oil and gas exploration, space exploration, and industrial automation.

- Optics and Photonics: Diamond’s optical clarity and hardness make it a preferred material for high-performance optical windows and lenses, particularly in environments where both durability and transparency across various wavelengths are required.